INSULATION products

Products

ALF-ALUMINA FIBER FABRICS

Short description

FIREPROOF-NON-FLAMMABLE TECHNICAL FABRICS

ALF-ALUMINA FIBER FABRICS

Alumina Fiber Fabrics

ALF™ is generally called Alumina Fiber. As the composite is 72% Alumina and 28% Silica, we name it Alumina Silica Fiber. The standard product/yarns are produced as a 7 micron diameter filament and are boron free. The 7 micron diameter allows superior flexibility compared to other available materials. Furthermore, because the fiber is boron-free, problems associated with the release of boron gas are not a factor. Performance and durability of Hiltex Alumina Silica Fiber is superior to other products presently available. ALF suffers almost no loss of mechanical strength at temperatures up to 1200º C.

We also have several types of fabrics, sleeves and yarns with 2% boron which can be used for applications approaching 1395ºC, this called out FB3 type.

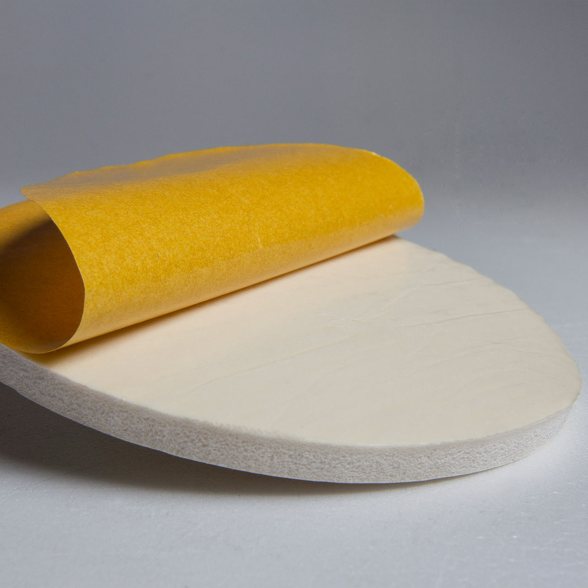

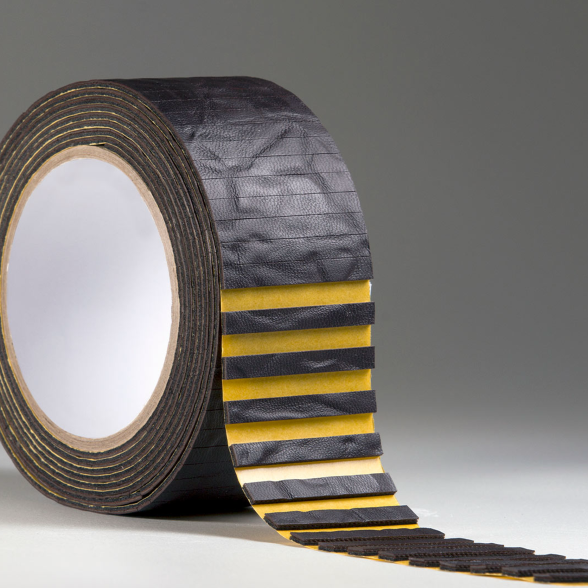

ALF is available as woven cloth, braided sleeve, tape, rope, yarn and sewing yarn.

Origin : NETHERLANDS

Details

Kategoriler: FIREPROOF TAPE SLEEVES, TAPES, ROPESDescription

Technical Date :

HILTEX ALF boron-free continuous Alumina-Silica fiber is classified into three types with different ratio of Alumina and Silica.

Alumina/silica ratios: 60/40%, 72/28% and 80/20%

Briefly, hardness of the fiber and the max temperature for continuous use goes up as ratio of alumina increases.

- HILTEX ALF 60/40 type has excellent flexibility and softness due to containing 40% of Silica. HILTEX ALF 60/40 type can continuously resist temperatures up to 1200℃.

- HILTEX ALF 72/28 type is the regular type of HILTEX ALF. Most of our products are made by using HILTEX ALF 72/28 yarn. This type of yarn can continuously resist temperatures up to 1250°C.

- HILTEX ALF 80/20 type has the best thermal resistance and hardness among all type of HILTEX ALF. This type can continuously resist the temperatures up to 1300°

Usage:

Appropriate for countless applications including the following:

- Automotive glass industry ( Alf sleeves to cover the rollers for the tempering process)

- Furnance linig steel industry ( especially in C.A.P.L.(Continuous annealing and processing line) and G.A.P.L(Galvanizing annealing and processing line), where temperatures are about 1100°C. To prevent dust coming from ceramic fiber blocks)

- Wire annealing (When ALF sleeve is installed in the pipe through which the metal wire runs it will avoid the wire from touching the metal of the pipe and becoming distorted)

- Thermal insulation rings

- Furnace linings

- Heat-shielding curtains

- Thermal insulation sealers or packing materials

- Thermal insulation coverings for thermocouples, cables and wires

- Roller covers for tempered glass plate manufacturing

- Filters for molten metals

- Spacers for heat treatment

- Abrasives for plastic whetstones

- Insulators around generator and aircraft/rocket engines

- Catalyst carriers

- Electrical and thermal insulators for diesel particulate filter (DPF) systems

- Alumina-silica fiber reinforced plastics (FRP), insulation and structural materials for cryogenic apparat uses

- Alumina-silica fiber reinforced metals (FRM)

![[ INSULATION MARKET ] Acoustics – Insulation – Technical Textile – Construction Building Materials and Industrial Chemicals](https://insulationmarket.com.tr/wp-content/uploads/insulation_logo-11-1.png)

![[ INSULATION MARKET ] Acoustics – Insulation – Technical Textile – Construction Building Materials and Industrial Chemicals](https://insulationmarket.com.tr/wp-content/uploads/insulation_logo-11.png)